|

|

|

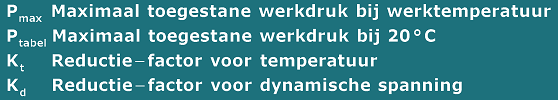

| Temperature | material hose | ||

|---|---|---|---|

| (°C) | 1.4541 | 1.4571 | 1.4301 |

| 20 | 1,00 | 1,00 | 1,00 |

| 50 | 0,92 | 0,94 | 0,92 |

| 100 | 0,86 | 0,87 | 0,83 |

| 150 | 0,83 | 0,84 | 0,75 |

| 200 | 0,79 | 0,80 | 0,68 |

| 250 | 0,74 | 0,75 | 0,63 |

| 300 | 0,71 | 0,72 | 0,59 |

| 350 | 0,68 | 0,69 | 0,56 |

| 400 | 0,67 | 0,68 | 0,54 |

| 450 | 0,66 | 0,67 | 0,53 |

| 500 | 0,65 | 0,66 | 0,52 |

| 550 | 0,56 | 0,58 | 0,52 |

| Movement | |||

|---|---|---|---|

| Flow | slight, slow movement | vibration, uniform movement | rhythmic, intermittent movement |

| static, slow flow | 1 | 0,80 | 0,40 |

| pulsating flow | 0,80 | 0,63 | 0,32 |

| rhythmic intermittent flow | 0,32 | 0,20 | upon request |

| Nominal bore (DN) |

ID (mm) |

OD (mm) |

Braid type |

Min. bendingradius static (mm) |

Min. bendingradius dynamic (mm) |

Max. pressure @ 20°C (bar) |

|---|---|---|---|---|---|---|

| 6 | 6,2 | 9,7 | S 00 | 15 | 80 | 24 |

| 6 | 6,2 | 10,8 | S 12 | 25 | 80 | 198 |

| 8 | 8,3 | 12,3 | S 00 | 16 | 125 | 17 |

| 8 | 8,3 | 13,7 | S 12 | 32 | 125 | 176 |

| 10 | 10,2 | 14,3 | S 00 | 18 | 130 | 12 |

| 10 | 10,2 | 15,7 | S 12 | 38 | 130 | 131 |

| 12 | 12,2 | 16,8 | S 00 | 20 | 140 | 9 |

| 12 | 12,2 | 18,2 | S 12 | 45 | 140 | 93 |

| 16 | 16,2 | 21,7 | S 00 | 28 | 160 | 7 |

| 16 | 16,2 | 23,3 | S 12 | 58 | 160 | 85 |

| 20 | 20,2 | 26,7 | S 00 | 32 | 170 | 3,5 |

| 20 | 20,2 | 28,3 | S 12 | 70 | 170 | 57 |

| 25 | 25,5 | 32,2 | S 00 | 40 | 190 | 3 |

| 25 | 25,5 | 34,2 | S 12 | 85 | 190 | 65 |

| 32 | 34,2 | 41,0 | S 00 | 50 | 260 | 2,5 |

| 32 | 34,2 | 43,0 | S 12 | 105 | 260 | 46 |

| 40 | 40,1 | 49,7 | S 00 | 60 | 300 | 2,5 |

| 40 | 40,1 | 52,0 | S 12 | 130 | 300 | 50 |

| 50 | 50,4 | 60,3 | S 00 | 70 | 320 | 1,6 |

| 50 | 50,4 | 62,6 | S 12 | 160 | 320 | 35 |

| 65 | 65,3 | 78,0 | S 00 | 115 | 460 | 1 |

| 65 | 65,3 | 81,2 | S 12 | 200 | 460 | 40 |

| 80 | 80,2 | 94,8 | S 00 | 130 | 700 | 1 |

| 80 | 80,2 | 98,0 | S 12 | 240 | 700 | 32 |

| 100 | 100,0 | 116,2 | S 00 | 160 | 750 | 0,8 |

| 100 | 100,0 | 119,4 | S 12 | 290 | 750 | 25 |

| 125 | 126,2 | 145,0 | S 00 | 500 | 1000 | 0,6 |

| 125 | 126,2 | 148,2 | S 12 | 500 | 1000 | 19 |

| 150 | 151,6 | 171,0 | S 00 | 700 | 1300 | 0,5 |

| 150 | 151,6 | 174,2 | S 12 | 700 | 1300 | 13 |

| 150 | 151,6 | 174,8 | S 42 | 700 | 1300 | 16 |

| 150 | 151,6 | 178,8 | S 52 | 700 | 1300 | 16 |

| 200 | 200,1 | 227,0 | S 00 | 860 | 1350 | 0,25 |

| 200 | 200,1 | 232,5 | S 12 | 860 | 1350 | 10 |

| 200 | 200,1 | 238,0 | S 42 | 860 | 1350 | 12 |

| 250 | 250,3 | 280,3 | S 00 | 1000 | 1600 | 0,2 |

| 250 | 250,3 | 286,0 | S 42 | 1000 | 1600 | 8 |

| 250 | 250,3 | 291,5 | S 52 | 1000 | 1600 | 12 |

| 300 | 300,3 | 333,1 | S 00 | 1270 | 2000 | 0,2 |

| 300 | 300,3 | 338,7 | S 42 | 1270 | 2000 | 6 |

| 300 | 300,3 | 344,7 | S 52 | 1270 | 2000 | 10 |

| Nominal bore (DN) |

ID (mm) |

OD (mm) |

Braid type |

Min. bendingradius static (mm) |

Min. bendingradius dynamic (mm) |

Max. pressure @ 20°C (bar) |

|---|---|---|---|---|---|---|

| 5 | 5,3 | 9,1 | S 00 | 15 | 85 | 32 |

| 5 | 5,3 | 10,2 | S 12 | 25 | 85 | 230 |

| 5 | 5,3 | 11,3 | S 22 | 35 | 125 | 380 |

| 6 | 6,0 | 10,1 | S 00 | 15 | 140 | 43 |

| 6 | 6,0 | 11,5 | S 12 | 25 | 140 | 350 |

| 6 | 6,0 | 12,9 | S 22 | 40 | 180 | 400 |

| 8 | 8,0 | 12,8 | S 00 | 20 | 180 | 50 |

| 8 | 8,0 | 14,4 | S 12 | 32 | 180 | 270 |

| 8 | 8,0 | 16,0 | S 22 | 50 | 220 | 400 |

| 10 | 10,0 | 15,9 | S 00 | 25 | 220 | 33 |

| 10 | 10,0 | 17,5 | S 12 | 38 | 220 | 220 |

| 10 | 10,0 | 19,1 | S 22 | 60 | 260 | 380 |

| 12 | 12,0 | 18,7 | S 00 | 30 | 250 | 32 |

| 12 | 12,0 | 20,3 | S 12 | 45 | 250 | 186 |

| 12 | 12,0 | 21,9 | S 22 | 70 | 300 | 340 |

| 16 | 16,0 | 24,4 | S 00 | 40 | 300 | 22 |

| 16 | 16,0 | 26,4 | S 12 | 58 | 300 | 190 |

| 16 | 16,0 | 28,4 | S 22 | 90 | 360 | 280 |

| Nominal bore (DN) |

ID (mm) |

OD (mm) |

Braid type |

Min. bendingradius static (mm) |

Min. bendingradius dynamic (mm) |

Max. pressure @ 20°C (bar) |

|---|---|---|---|---|---|---|

| 20 | 20,2 | 29,2 | S 00 | 45 | 280 | 8 |

| 20 | 20,2 | 31,2 | S 12 | 70 | 280 | 129 |

| 20 | 20,2 | 33,2 | S 22 | 70 | 280 | 168 |

| 25 | 25,2 | 34,2 | S 00 | 50 | 320 | 6 |

| 25 | 25,2 | 36,2 | S 12 | 85 | 320 | 80 |

| 25 | 25,2 | 38,2 | S 22 | 85 | 320 | 136 |

| 32 | 33,7 | 42,7 | S 00 | 60 | 380 | 4 |

| 32 | 33,7 | 45,0 | S 12 | 105 | 380 | 87 |

| 32 | 33,7 | 47,2 | S 22 | 105 | 380 | 105 |

| 40 | 40,0 | 55,0 | S 00 | 75 | 420 | 2,5 |

| 40 | 40,0 | 57,3 | S 12 | 130 | 420 | 50 |

| 40 | 40,0 | 59,5 | S 22 | 130 | 420 | 82 |

| 50 | 50,0 | 65,0 | S 00 | 90 | 490 | 3 |

| 50 | 50,0 | 68,2 | S 12 | 160 | 490 | 70 |

| 50 | 50,0 | 71,3 | S 22 | 160 | 490 | 77 |

| 65 | 65,0 | 81,0 | S 00 | 110 | 590 | 2 |

| 65 | 65,0 | 84,2 | S 12 | 200 | 590 | 42 |

| 65 | 65,0 | 87,3 | S 22 | 200 | 590 | 66 |

| 80 | 79,8 | 98,3 | S 00 | 135 | 700 | 1,6 |

| 80 | 79,8 | 101,5 | S 12 | 240 | 700 | 41 |

| 80 | 79,8 | 104,6 | S 22 | 240 | 700 | 64 |

| 100 | 99,8 | 117,8 | S 00 | 160 | 900 | 1,6 |

| 100 | 99,8 | 121,0 | S 12 | 290 | 900 | 32 |

| 100 | 99,8 | 124,1 | S 22 | 290 | 900 | 57 |

| 125 | 125,6 | 146,0 | S 00 | 600 | 1200 | 1 |

| 125 | 125,6 | 149,2 | S 12 | 600 | 1200 | 23 |

| 125 | 125,6 | 152,6 | S 22 | 600 | 1200 | 43 |

| 150 | 149,7 | 178,5 | S 00 | 1100 | 1800 | 0,5 |

| 150 | 149,7 | 182,5 | S 42 | 1100 | 1800 | 16 |

| 150 | 149,7 | 186,5 | S 52 | 1100 | 1800 | 30 |

| 200 | 200,0 | 232,5 | S 00 | 1400 | 2200 | 0,3 |

| 200 | 200,0 | 238,0 | S 42 | 1400 | 2200 | 14 |

| 200 | 200,0 | 243,5 | S 52 | 1400 | 2200 | 20 |

| 250 | 250,0 | 285,0 | S 00 | 1650 | 2600 | 0,2 |

| 250 | 250,0 | 290,5 | S 42 | 1650 | 2600 | 8 |

| 250 | 250,0 | 296,0 | S 52 | 1650 | 2600 | 16 |

| 300 | 300,0 | 337,4 | S 00 | 2100 | 3300 | 0,1 |

| 300 | 300,0 | 343,0 | S 42 | 2100 | 3300 | 6 |

| 300 | 300,0 | 349,0 | S 52 | 2100 | 3300 | 11 |

|